S2K Commerce - Products Dropdown

S2K Commerce - Products Dropdown

S2K Commerce - Shopping Cart

S2K Commerce - Shopping Cart

Web Content Viewer

Web Content Viewer

onsep Manufacturing CAPABILITIES

We are proud to offer diverse options to meet your sealing & repair needs. Our in-house tooling, extensive inventory and material processing affords us the manufacturing control to provide our customers with faster fulfillment and expeditious shipping. We take pride in our quality products and scrutinize each component prior to shipping to ensure maximum customer satisfaction.

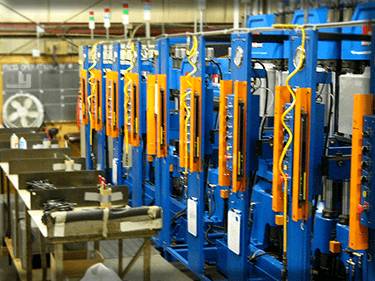

Rubber Compression

With our 9 conventional & vacuum compression presses ranging from 100 to 600 ton, we have the capabilities to mold a large array of products in a broad range of materials and sizes up to 38”.

Molding

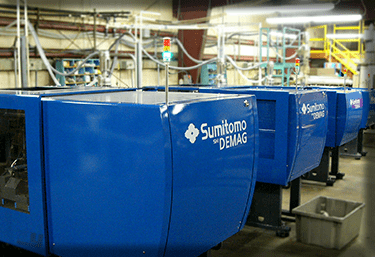

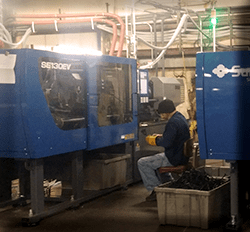

Plastic Injection

Our innovative five hopper plastics drying system supplies material to our 5 injection molding machines securing a high quality finished product.

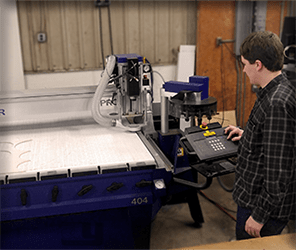

Plastics CNC Machining

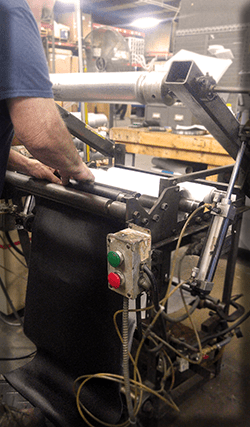

Gasket Trimming

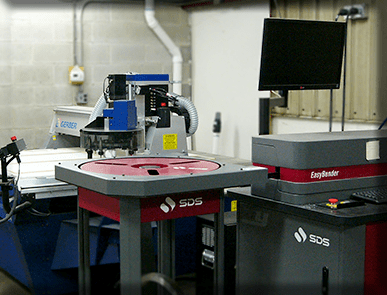

Gasket cutting requires precision to ensure a tight tolerance and effective seal. Konsep can die-cut or machine gaskets depending on customer’s requirements utilizing our Gerber CNC Router, Easy Bender & computer controlled steel rule bender equipment. Whether it's foam, rubber, ptfe, graphite, Teflon, vegetable fiber or adhesive backed, we have the equipment necessary to ensure a high quality, precisely machined and die-cut gasket to meet your industry requirements.

Forming

Ancillary Services

Back

Available MaterialsProfile Selection Chart

Component Request

onsep Manufacturing EQUIPMENT

Our State-of-the-Art manufacturing equipment and tooling enables us to have maximum control over quality, consistency and product standards in addition to reduced lead times.

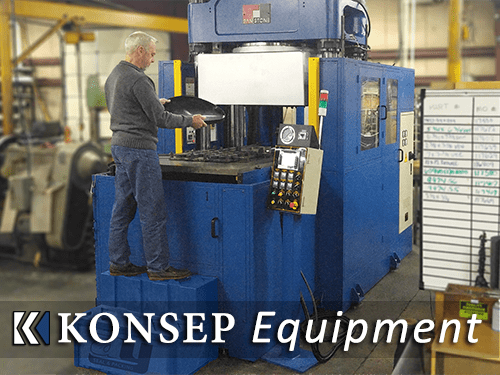

Compression Presses

| Qty | Platen Size | Tonnage |

| 4 | 16" x 18" | 250 |

| 4 | 16" x 18" | 250-Vacuum |

| 4 | 42" x 42" | 600-Vacuum |

| 1 | 24" x 24" | 300 |

| 1 | 36" x 36" | 2500 |

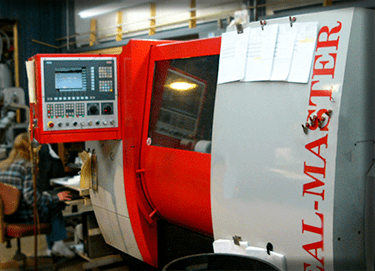

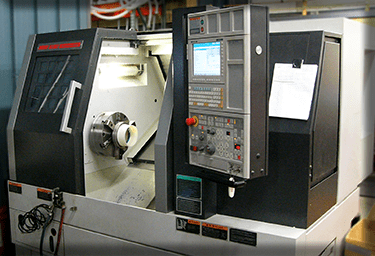

CNC Machines

| Machine | Features | Capabilities |

| DMH | assorted functions | specialty seals |

| Mori Dura Turn 2030 | 10" Chuck/18 tool turret | Hard plastic, Steel |

| Mori Dura Turn 2050 | 12" Chuck/Live Tooling | Hard plastic, Steel |

| Trah Vertical Mill | Proto Trah VM Control | Hard plastic, Steel |

| Bridgeport CNC | Okuma Controls | Steel |

| Gerber Router | CNC Control | Gasket/Trim Dies |

| Easy-Bender Steel Rule | CNC Control | Trim Dies |

Injection Press

| Manufacturer | Tonnage (mm/us) |

| 2014 Sumitomo SE130EV | 130 |

| 2015 Sumitomo SE75EV | 75 |

| 2015 Sumitomo SE100V | 100 |

| 2014 Sumitomo SE50EV | 50 |

| 1988 Nissei | 360/400 |

Machine Shop

| Machine | Capabilities |

| Auto-tool CNC Machine Ctr | 1/4" - 24" mold production |

Support Machines

| Qty | Type | Function |

| 1 | 5-Hopper Plastic Drying System | Resin Drying |

| 3 | Clicker | Trim & Gaskets |

| 2 | Knife Trimmer | Trimming |

| 4 | Granulator | Recycle Plastic |

Back

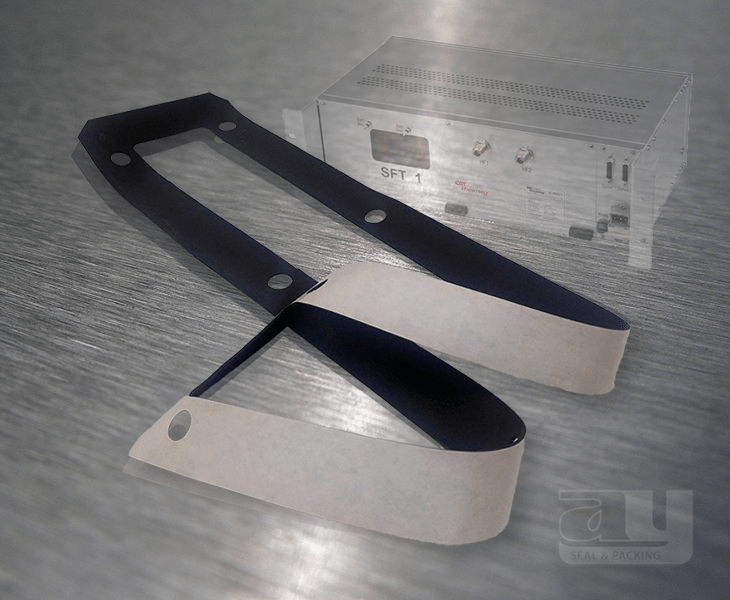

onsep Manufacturing PROJECT PORTFOLIO

Each custom made-to-order component has distinct performance requirements that demand a unique design & manufacturing plan. Our knowledgeable and experienced engineers and manufacturing team can easily recognize the individual specifications and requirements of a project, taking on challenges with a proactive and comprehensive plan. Regardless of your business or industry, you need an efficient and reliable sealing component to ensure maximum productivity. The AY Team welcomes new challenges to solve your sealing dilemma. Here are just a few recent made-to-order opportunities where our ingenuity 'saved the day'.

Manufactured for: Laird Technologies

Application: Filter Housing

Materials: Neoprene, SBR, EPDM

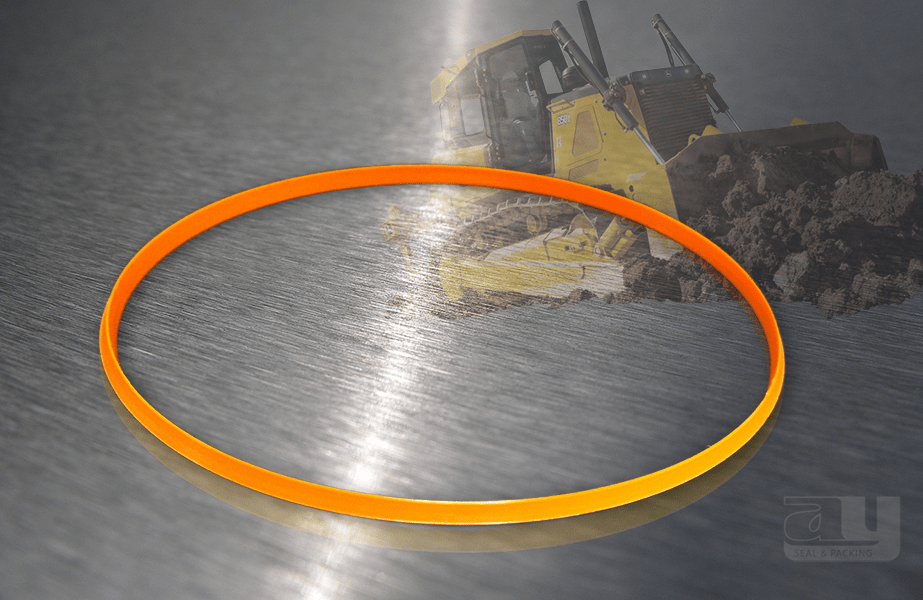

Application: Install. & Removal Tool for JD Equip.

Materials: Hytrel

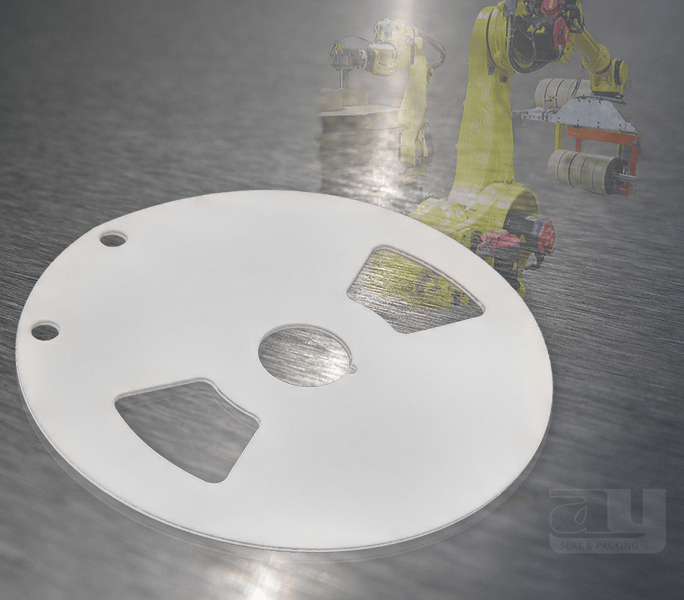

Manufactured for: Mott's

Application: Food Production

Materials: PTFE

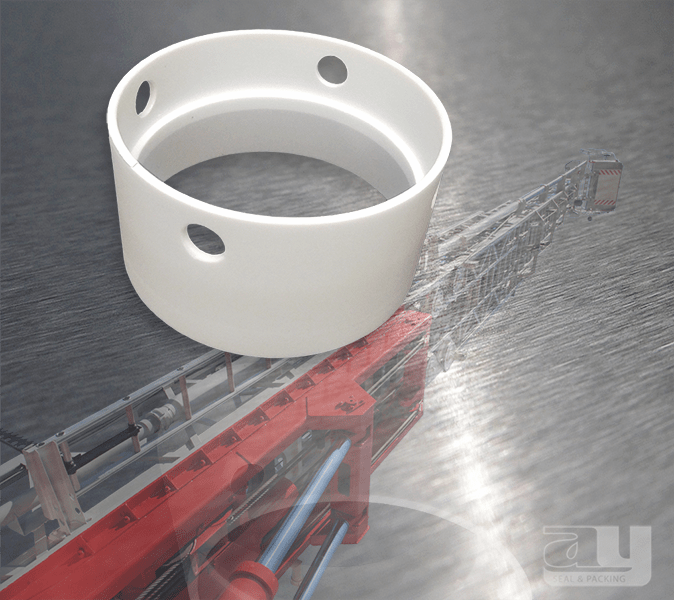

Manufactured for: Fire & Rescue organizations

Application: Turntable Fire Truck Ladder

Materials: Delrin® 500AF

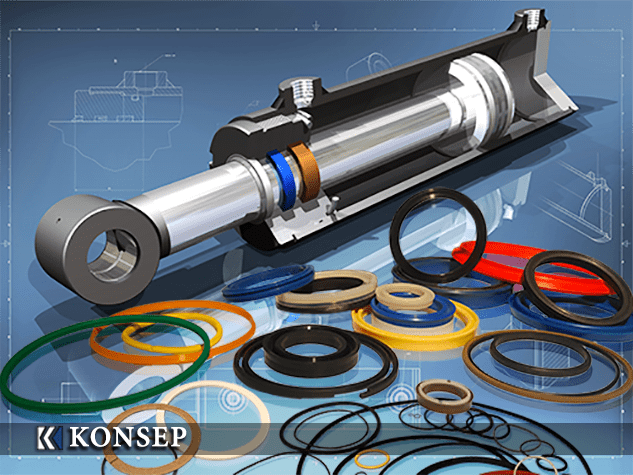

Manufactured for:Industrial, Commercial, Military, Agricultural, Marine & More!

Applications:

Materials: NYL, URE, NBR, Fabric, Hytrel, PUR, etc

Frequently ordered items:Vee Packing Components, Piston Cups, U-Cups, Back-up Rings, Wearbands, Wipers, W Packing, Bearings & Seal Retainers

Back

onsep Manufacturing About Us

Since 1982 Konsep Company, a division of Allegheny York, has been molding thermoplastic and engineering grade materials including glass and mineral-filled. We utilize 5 injection presses with a scope of 85 to 400 ton to do both short and long runs. Konsep Company also produces compression molding with 12 presses ranging from 250 to 2500 ton to mold NBR, Viton, Duck & Rubber and other compounds.

Konsep Company readily manufactures wipers, seals, backup rings, bearings and guide rings to meet your demands utilizing advanced rapid prototyping technology. Parts can be made from over 100 profiles for same-day delivery using our extensive inventory of available materials.

Time to market should be a critical consideration in your selection process. Our in-house design staff is here to help evaluate your design and material needs. Minor changes in an existing mold design can also dramatically reduce tooling costs, improve part yield, and speed production cycles.

The largest single cost in the set-up of a production run is the tooling cost. Often manufacturers outsource tooling stage which dramatically impacts the end cost. Our in-house CAD/CAM system, mills, lathes and brand new Bridgeport® Auto-Tool CNC Machining Center affords us the ability to provide in house tooling to save our customers time and money!

Providing a high quality component congruent with our customer's requirements that is received punctually and satisfactorily are paramount for Konsep. You may rest assured, from start to finish, our in-house design, tooling and state of the art production will meet or exceed your expectations. Tight tolerances, tricky configurations and exotic materials are welcomed by our team. At Konsep Company, we take pride on our ability to take on your most challenging production issues and give you a product we'll both be proud of.

Back

onsep Manufacturing Take a Tour!

Get an in-depth look at our facility & operations through our sensational new Allegheny York and Konsep Company video!

Allegheny York from Steelwire Creative, LLC on Vimeo.