Z6_EL9QHKG10GPM20IJGE61AK10O0

{}

Z7_JA82HK02LGUEA0A51JF8DB3G75

/wps/contenthandler/!ut/p/digest!Wnby4_fflqEyILg4H9e80A/pm/oid:--portletwindowid--@oid:Z6_EL9QHKG10GPM20IJGE61AK10O0

/wps/contenthandler/!ut/p/digest!Wnby4_fflqEyILg4H9e80A/um/secure/currentuser/profile?expandRefs=true

- PARKER® PRODUCTS

- PARKER® STANDARD MOLYTHANE LOADED LIP SEAL POLYPAKS®

- PARKER® DEEP MOLYTHANE LOADED LIP SEAL POLYPAKS®

- PARKER® BEVELED LIP MOLYTHANE LOADED LIP SEAL POLYPAKS®

- PARKER® MOLYTHANE PIP(PRESSURE INVERTING PEDESTAL) RING

- PARKER® STANDARD MOLYTHANE UR NON-SYMMETRICAL ROD U-CUP

- PARKER® HI-TEMPERATURE DOUBLE LIP 4300 BT ROD U-CUPS

- PARKER® SYMMETRICAL MOLYTHANE US ROD or PISTON U-CUPS

- PARKER® STANDARD MOLYTHANE NON-SYMMETRICAL PISTON U-CUP

- PARKER® PSP STYLE 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

- PARKER® PSP-A 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

- PARKER® STANDARD MOLYTHANE CS PISTON CUP

- PARKER® THIN LIP MOLYTHANE CT PISTON CUP

- PARKER® STANDARD MOLYTHANE MODULAR U-CUP BACK UPS

- SEAL KITS & REPLACEMENT PARTS

- BUSH HOG® REPLACEMENT SEAL KITS & COMPONENTS

- ATLAS® REPLACEMENT SEAL KITS & COMPONENTS

- BARKO® REPLACEMENT SEAL KITS & COMPONENTS

- BLACKHAWK® REPLACEMENT SEAL KITS & COMPONENTS

- BOBCAT® REPLACEMENT SEAL KITS & COMPONENTS

- CASE® REPLACEMENT SEAL KITS & COMPONENTS

- CAT® REPLACEMENT SEAL KITS & COMPONENTS

- CHARLYNN® REPLACEMENT SEAL KITS & COMPONENTS

- CLARK® REPLACEMENT SEAL KITS & COMPONENTS

- COMMERCIAL®PARKER REPLACEMENT SEAL KITS & COMPONENTS

- COPELAND® REPLACEMENT SEAL KITS & COMPONENTS

- CORMACH® REPLACEMENT SEAL KITS & COMPONENTS

- CUSTOM HOIST® REPLACEMENT SEAL KITS & COMPONENTS

- DEMPSTER® REPLACEMENT SEAL KITS & COMPONENTS

- DOOSAN® REPLACEMENT SEAL KITS & COMPONENTS

- ENERGY® REPLACEMENT SEAL KITS & COMPONENTS

- ENERPAC® REPLACEMENT SEAL KITS & COMPONENTS

- ESCO® REPLACEMENT SEAL KITS & COMPONENTS

- EUCLID® REPLACEMENT SEAL KITS & COMPONENTS

- FASSI® REPLACEMENT SEAL KITS & COMPONENTS

- FIAT ALLIS® REPLACEMENT SEAL KITS & COMPONENTS

- FORD® REPLACEMENT SEAL KITS & COMPONENTS

- GALBREATH® REPLACEMENT SEAL KITS & COMPONENTS

- HEIL® REPLACEMENT SEAL KITS & COMPONENTS

- HITACHI® REPLACEMENT SEAL KITS & COMPONENTS

- HUSKY® REPLACEMENT SEAL KITS & COMPONENTS

- HYDRO-LINE® REPLACEMENT SEAL KITS & COMPONENTS

- HYSTER® REPLACEMENT SEAL KITS & COMPONENTS

- INGERSOLL-RAND® REPLACEMENT SEAL KITS & COMPONENTS

- INTL HARVESTER® REPLACEMENT SEAL KITS & COMPONENTS

- IOWA MOLD® REPLACEMENT SEAL KITS & COMPONENTS

- JCB® REPLACEMENT SEAL KITS & COMPONENTS

- JLG® REPLACEMENT SEAL KITS & COMPONENTS

- JOHN DEERE® REPLACEMENT SEAL KITS & COMPONENTS

- KALMAR® REPLACEMENT SEAL KITS & COMPONENTS

- KOBELCO® REPLACEMENT SEAL KITS & COMPONENTS

- KOMATSU® REPLACEMENT SEAL KITS & COMPONENTS

- KUBOTA® REPLACEMENT SEAL KITS & COMPONENTS

- LABOUNTY® REPLACEMENT SEAL KITS & COMPONENTS

- Leeboy® REPLACEMENT SEAL KITS & COMPONENTS

- LEACH® REPLACEMENT SEAL KITS & COMPONENTS

- LIEBHERR® REPLACEMENT SEAL KITS & COMPONENTS

- LINKBELT® REPLACEMENT SEAL KITS & COMPONENTS

- LOADMASTER® REPLACEMENT SEAL KITS & COMPONENTS

- LOGHOG® REPLACEMENT SEAL KITS & COMPONENTS

- MAILHOT® REPLACEMENT SEAL KITS & COMPONENTS

- WESTERN®/MEYER® REPL SNOWPLOW KITS & COMPONENTS

- MILLER® REPLACEMENT SEAL KITS & COMPONENTS

- MONARCH® REPLACEMENT SEAL KITS & COMPONENTS

- NEW HOLLAND® REPLACEMENT SEAL KITS & COMPONENTS

- NISSAN® REPLACEMENT SEAL KITS & COMPONENTS

- NORGREN® REPLACEMENT SEAL KITS & COMPONENTS

- PARKER® REPLACEMENT SEAL KITS & COMPONENTS

- PETTIBONE®REPLACEMENT SEAL KITS & COMPONENTS

- POWERTRAIN® REPLACEMENT SEAL KITS & COMPONENTS

- PRENTICE® REPLACEMENT SEAL KITS & COMPONENTS

- REXROTH® REPLACEMENT SEAL KITS & COMPONENTS

- SAMSUNG® REPLACEMENT SEAL KITS & COMPONENTS

- SHEFFER® REPLACEMENT SEAL KITS & COMPONENTS

- TAYLOR-DUNN® REPLACEMENT SEAL KITS & COMPONENTS

- TEREX® REPLACEMENT SEAL KITS & COMPONENTS

- TOWMOTOR® REPLACEMENT SEAL KITS & COMPONENTS

- TIMBERPRO® REPLACEMENT SEAL KITS & COMPONENTS

- TOYOTA® REPLACEMENT SEAL KITS & COMPONENTS

- TROJAN® REPLACEMENT SEAL KITS & COMPONENTS

- US TRUCK CRANE® REPLACEMENT SEAL KITS & COMPONENTS

- VERSALIFT® REPLACEMENT SEAL KITS & COMPONENTS

- VOLVO® REPLACEMENT SEAL KITS & COMPONENTS

- WALTCO® REPLACEMENT SEAL KITS & COMPONENTS

- WESTERN® REPLACEMENT SEAL KITS & COMPONENTS

- U CUPS

- POLYPAK®/STANDARD O-RING LOADED LIP SEAL - INCH

- POLYPAK®/ DEEP O-RING LOADED LIP SEAL - INCH

- POLYPAK®/BEVELED O-RING LOADED LIP SEAL - INCH

- PR - PIP RING (PRESSURE INVERTING PEDESTAL RING) - INCH

- DZ - DEEP Z ROD SEAL - INCH

- UNRR - POLYURETHANE RIBBED ROD SEAL - INCH

- UNRR - POLYURETHANE RIBBED ROD SEAL-METRIC

- BS - DOUBLE LIP URETHANE ROD SEAL - INCH

- BS - DOUBLE LIP URETHANE ROD SEAL - METRIC

- MLLB - BEVELED O-RING LOADED LIP SEAL - METRIC

- BSLL - DOUBLE LIP ORING LOADED URETHANE ROD SEAL - INCH

- BS-B - URETHANE DOUBLE LIP ROD SEAL w/POM BACKUP - INCH

- BS-B -URETHANE DBL LIP ROD SEAL w/POM BU-METRIC

- BT - 4300® HIGH TEMP DOUBLE LIP ROD U-CUP - INCH

- BD - DOUBLE LIP O-RING LOADED ROD SEAL w/BACKUP - INCH

- BD - DOUBLE LIP O-RING LOADED ROD SEAL w/BACKUP -METRIC

- UNR - URETHANE ASYMMETRICAL ROD SEAL - INCH

- MA30 - URETHANE ASYMMETRICAL ROD SEAL - METRIC

- MA30B-URETHANE ROD SEAL w/NYLON BACKUP - METRIC

- MA35 - URETHANE SYMMETRICAL DOUBLE LIP ROD SEAL -METRIC

- C1 - NITRILE ASYMMETRICAL ROD U-CUP - METRIC

- MURH - NITRILE ASYMMETRICAL ROD U-CUP - METRIC

- MA24 - NITRILE ASYMMETRICAL ROD U-CUP - METRIC

- US- URETHANE SYMMETRICAL ROD or PISTON U-CUP - INCH

- MA25 - URETHANE SYMMETRICAL ROD/PISTON U-CUP - METRIC

- 8400 - NITRILE SYMMETRICAL U-CUP - INCH

- 6226 - NITRILE SYMMETRICAL (AN) U-CUP - INCH

- MA21 - NITRILE SYMMETRICAL PISTON or ROD U-CUP - METRIC

- MA22 - NITRILE SYMMETRICAL PISTON or ROD U-CUP - METRIC

- UCH - NITRILE NON-STANDARD HOMOGENEOUS U-CUP - INCH

- UCF - FABRIC REINFORCED NITRILE U-CUP - INCH

- UCL - LEATHER U-CUP w/NITRILE FILLER - INCH

- UNP - URETHANE ASYMMETRICAL PISTON U-CUP - INCH

- UNP - AN - THIN LIP URETHANE PISTON U-CUP - INCH

- MA28B/UNP Piston U-CUP w/OD BACKUP INCH & METRIC

- MA28 - URETHANE ASYMMETRICAL PISTON U-CUP-METRIC

- BP - DOUBLE LIP ORING LOADED URETHANE PISTON SEAL -INCH

- MA20 - NITRILE U-CUP w/STEPPED NYLON HEEL - METRIC

- RSE- URE PISTON U-CUP w/STEPPED BACKUP/BEARING- Metric

- C2 - NITRILE ASYMMETRICAL PISTON U-CUP - METRIC

- MUPH - NITRILE ASYMMETRICAL PISTON U-CUP - METRIC

- MA23 - NITRILE ASYMMETRICAL PISTON U-CUP - METRIC

- OUY - NITRILE PISTON U-CUP w/POM BACKUP - METRIC

- W1-3PC NBR/POM/TFE HGH PRESSURE POWERWASHER SEAL-METRIC

- W2 - 1PC NBR/FAB LOW PRESSURE POWERWASHER SEAL - METRIC

- W3 - 2 PC LOW PRESSURE POWERWASHER SEAL - METRIC

- ROD SEALS / BUFFER RINGS

- TR0 - 3PC NITRILE ROD T-SEAL w/NYLON BACKUPS- INCH

- TDI - Hunger® 2pc Urethane/PTFE Rod Seal - Metric

- AS7 - 2 PC DOUBLE ACTING BTFE/NBR ROD SEAL

- CAT® 2 PC REPL STEPPED BTFE/NBR ROD BUFFER SEAL - INCH

- AS2 - 2 PC STEPPED BTFE/NBR ROD BUFFER SEAL - INCH

- AS2 - 2 PC STEPPED BTFE/NBR ROD BUFFER SEAL - METRIC

- CAT®/CASE® Repl 1pc PU or NBR BUFFER RING - INCH

- MBRU - 1 PC RECTANGULAR URETHANE BUFFER RING - METRIC

- CBR/CTB - CAT®/CASE® U-CUP BUFFER RING - INCH

- MBR - URETHANE U-CUP STYLE BUFFER RING - METRIC

- BU - 2PC URETHANE/POM ROD BUFFER SEAL W/BACKUP - METRIC

- SM - NITRILE/POM/NYLON 3 PC RIBBED ROD SEAL - METRIC

- MD - NITRILE ROD SQUEEZE SEAL w/POM BACKUP - METRIC

- S8 - 2 PC BONDED ROD SQUEEZE SEAL - METRIC

- WIPERS

- 940 - URETHANE AN STYLE ROD WIPER - INCH

- 940 AN TYPE NON-STANDARD URETHANE ROD WIPER - INCH

- U - URETHANE UNIVERSAL "D" STANDARD ROD WIPER - INCH

- NON-STANDARD URETHANE UNIVERSAL "D" ROD WIPER - INCH

- U - NBR UNIVERSAL "D" STANDARD WIPER CORD - INCH

- A40 - NITRILE & URETHANE STANDARD ROD WIPER-METRIC

- U-R - URETHANE "D" ROD WIPER w/ RIBBED HEEL -INCH

- 842 - URETHANE UMBRELLA ROD WIPER - INCH & METRIC

- 842 - URETHANE UMBRELLA TOP ROD WIPER - METRIC

- A37 - JIS URETHANE KWI ROD WIPER - METRIC

- ENERPAC® REPLACEMENT URETHANE ASC STYLE WIPER

- 33 - RECTANGULAR BASE NBR SINGLE LIP ROD WIPER - INCH

- A39 - THIN WALL NITRILE SINGLE LIP ROD WIPER - METRIC

- NW - MOLY/NYLON ROD WIPER/SCRAPER - INCH

- NW - MOLY/NYLON ROD WIPER/SCRAPER - METRIC

- K - DOUBLE LIP URETHANE ANGLED BASE ROD WIPER - INCH

- K - DOUBLE LIP NITRILE WIPER CORD - INCH

- KB - SINGLE LIP URETHANE ROD WIPER - INCH & METRIC

- 7580 - "H" STYLE DOUBLE LIP NITRILE ROD WIPER - INCH

- H - "H" STYLE DOUBLE LIP URETHANE ROD WIPER - INCH

- H -SPECIAL SIZE HIGH LIP URETHANE "H" STYLE ROD WIPER

- 8600 - "H" STYLE DOUBLE LIP NITRILE ROD WIPER - INCH

- AY - "H" STYLE DOUBLE LIP URETHANE ROD WIPER - METRIC

- SDR - "H" STYLE DOUBLE LIP NITRILE ROD WIPER - METRIC

- ORK - CASCADE® REPLACEMENT URETHANE ROD WIPER - INCH

- OUTSIDE DIAMETER LIP URETHANE BORE WIPER

- ASC - LIGHT DUTY NITRILE OR URETHANE ROD WIPER - INCH

- A41- SINGLE LIP URE/NBR STEPPED ROD WIPER - Metric

- DA17 - DOUBLE LIP STEPPED NITRILE ROD WIPER - METRIC

- DA24 - DOUBLE ACTING DOUBLE LIP URETHANE WIPER - METRIC

- S34 - SEAL-GUARD® 2 PC BRONZE/NBR WIPER/SCRAPER - INCH

- 504 - METAL ENCASED BRONZE/STEEL/NBR ROD SCRAPER -INCH

- MS28776 - AN STYLE 2 PC METAL/NBR WIPER/SCRAPER- INCH

- ME - METAL ENCASED NITRILE or URETHANE ROD WIPER - INCH

- AMJ - METAL ENCASED URETHANE ROD WIPER - METRIC

- CAT® REPL METAL ENCASED DBL LIP URE ROD WIPER - INCH

- AMH - DBL LIP METAL ENCASED URETHANE ROD WIPER - METRIC

- AM43 - METAL ENCASED NITRILE ROD WIPER - METRIC

- AM44 - METAL ENCASED URETHANE ROD WIPER - METRIC

- AM46 - METAL ENCASED URETHANE LINK PIN WIPER - METRIC

- AM47 - METAL ENCASED NITRILE ROD LINK PIN WIPER - METRI

- AM48 - METAL ENCASED URETHANE LINK PIN WIPER - METRIC

- TW100 - 2PC BTFE/NBR SINGLE LIP SCRAPER/WIPER - METRIC

- TW500 - 2PC BTFE/NBR DOUBLE LIP SCRAPER/WIPER - METRIC

- PISTON SEALS

- PR - CAST IRON METAL PISTON RINGS - INCH

- UP - STEEL w/TFE SEAL & WEARBANDS UNITIZED PISTON SEAL

- 12 - 1PC 2 DURO URETHANE UNIRING PISTON SEAL - INCH

- AS700 - 2 PC RECTANGULAR GTFE/NBR PISTON SEAL - INCH

- AS800 - 2 PC TFE/NBR PISTON SEAL - INCH

- AS800P - 2 PC SQUARE URETHANE/NBR PISTON SEAL - INCH

- AS800B - 2 PC BTFE/NBR PISTON SEAL - INCH

- AS900 - 2 PC RECTANGULAR GTFE/NBR PISTON SEAL - INCH

- AS900B - 2 PC RECTANGULAR BTFE/NBR PISTON SEAL - INCH

- AS9 - SPECIAL SIZE 2 PC CTFE/NBR PISTON SEAL - INCH

- AS980 - CAT® REPL 2 PC GTFE/NBR HEAVY DUTY TFE - INCH

- AS2 -2 PC STEPPED BTFE/NBR PISTON BUFFER SEAL - METRIC

- AS2 - 2 PC STEPPED BTFE/NBR PISTON BUFFER SEAL - INCH

- AS7 - 2 PC BTFE/NBR HEAVY DUTY PISTON SEAL - INCH

- AS7 - 2 PC BTFE/NBR HEAVY DUTY PISTON SEAL - METRIC

- AS990 - 2 PC RECTANGULAR BTFE/NBR PISTON SEAL - METRIC

- AS600 - 2 PC RECTANGULAR HYTREL®/NBR PISTON SEAL - INCH

- PSP - 2 PC RECTANGULAR URE®/NBR PISTON SEAL - INCH

- PSP-A 2 PC NEW STYLE URE®/NBR PISTON SEAL - INCH

- CP - 2 PC RECTANGULAR URE®/NBR PISTON CROWN SEAL - INCH

- AS5/6/PSP-2 PC RECTANGULAR PU®/NBR PISTON SEAL - METRIC

- AS4 - 2 PC URETHANE/NBR PISTON SEAL - METRIC

- NO - 2PC FAB/NBR PISTON SEAL w/NYLON BACK UP - METRIC

- 714 - 2 PC STEPCUT NYLON PISTON SEAL w/SQR ENGZR - INCH

- OK - 2 PC STEPCUT NYLON PISTON SEAL w/SQR ENGZR -METRIC

- 914 - 2 PC STEPCUT NYLON PISTON SEAL w/OVAL ENGZR -INCH

- CAT® 2PC REP NYLON PISTON SEAL w/OVAL NBR EXPNDR - INCH

- CAT® 2PC REP NYLON PISTON SEAL w/OVAL NBR EXPNDR - MM

- TP0 - 3 PC NITRLIE PISTON T-SEAL w/NYLON BACKUPS- INCH

- TPT - WIDE BASE 3 PC NITRLIE PISTON T-SEAL - INCH

- M4 - 3PC FAB/NBR/NYLON PISTON VEE SET SEAL - METRIC

- AS880 - 3PC GTFE/NBR PISTON SEAL w/2 O-RINGS - INCH

- DS - 3PC NBR w/POM BEARINGS DELTA PISTON SEAL - INCH

- DSM - 3PC NBR w/POM BEARINGS DELTA PISTON SEAL - METRIC

- MDL - 3PC DOUBLE ACTING NBR/POM PISTON SEAL - METRIC

- ASQ - 3 PC BTFE/QUAD W/ORING PISTON SEAL W/ORING - INCH

- ASQ - 3 PC BTFE/QUAD W/ORING PISTON SEAL W/ORING-METRIC

- ASQ5 - 4PC BTFE/QUAD PISTON SEAL w/ 2 NBR EXPANDERS

- 4PE/4PV - 4 PC BTFE or URE/NBR/NYLON PISTON SEAL - INCH

- 4PT - 4 PC BTFE/NBR/NYLON CAT®TYPE PISTON SEAL - INCH

- 4PMM - 4 PC BTFE/NBR/NYLON PISTON SEAL - METRIC

- DAS - 5 PC NITRILE/NYLON/POM PISTON SEAL - INCH

- DAS - 5 PC NITRILE/NYLON/POM PISTON SEAL - METRIC

- MHM - JCB® REPL 5 PC SQUARE BACK PISTON SEAL - METRIC

- DSM - 5 PC NITRILE/NYLON/POM PISTON SEAL - METRIC

- GD1KK - 6PC NITRILE/NYLON/POM PISTON SEAL - METRIC

- PISTON CUPS

- DR - SINGLE ACTING FABRIC/NITRILE PISTON CUP - INCH

- SC - SINGLE ACTING HOMOGENOUS NITRILE PISTON CUP - INCH

- CS - SINGLE ACTING URETHANE PISTON CUP - INCH

- CT - SINGLE ACTING THIN WALL URETHANE PISTON CUP - INCH

- MIL - Miller A®, JW® & HW® REPL PISTON CUP - INCH-INCH

- DK - DOUBLE ACTING NBR/STEEL PISTON CUP - INCH

- DE-SNGL ACTING NBR/STEEL PISTON CUP w/CUSHION

- DK - DOUBLE ACTING NBR/STEEL PISTON CUP - METRIC

- DP - DBL ACTING NBR/STEEL PISTON CUP w/CUSHION - METRIC

- CB - DOUBLE ACTING NBR/STEEL PISTON CUP - INCH

- TDH - DBL ACTING NBR/STEEL PISTON CUP w/SPRING - METRIC

- BMP -SINGLE ACTING URETHANE PISTON CUP W/CUSHION - INCH

- PNEUMATIC SEALS

- PP - URE or NBR PNEUMATIC CUSHION SEAL - METRIC

- EL - URE or NBR COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- EM - URETHANE COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- E9 - NBR/MTL COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- E8 - NBR/URE COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- EU - URETHANE COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- PDU - NBR COMBINATION PNEUMATIC ROD SEAL/WIPER - METRIC

- PSD - NITRILE PNEUMATIC PISTON SEAL - METRIC

- PPD - NITRILE PNEUMATIC PISTON SEAL - METRIC

- PZ - NITRILE PNEUMATIC PISTON SEAL - METRIC

- KSP - NITRILE PNEUMATIC PISTON SEAL - METRIC

- Z8 - URE or NBR PNEUMATIC PISTON U-CUP - METRIC

- E4 - URE or NBR PNEUMATIC PISTON U-CUP

- O RINGS

- O-RINGS - 568 DASH SIZE N70,N90,V75,HN70,S70,P90 - INCH

- O-RINGS - BOSS FITTING STANDARD SIZE N70,N90,V75 - INCH

- SQUARE & O-RING N70 CORD STOCK - INCH & METRIC

- O-RINGS - JIS, EURO, N70,N90,V75,HN70,S70,P90 - METRIC

- QUAD RINGS - X-CUT N70 NITRILE - INCH

- SQUARE LATHE CUT N70 NITRILE RINGS - INCH

- O-RING, FLANGE SEAL & BACK UP KITS

- O-RING ACCESSORIES & TOOLS

- BACKUP RINGS

- 8 - CONTOURED N90 NITRILE O-RING BACKUP - INCH

- MS27595 - SOLID TEFLON® O-RING BACK UP - INCH

- MS28774 - SPLIT TEFLON® O-RING BACK UP - INCH

- MS28782 - SPIRAL TEFLON® O-RING BACK UP - INCH

- MS28783 - SPIRAL TEFLON® O-RING BACK UP - INCH

- 19/51 - FLAT 95A URETHANE O-RING BACKUP - INCH

- MBH - HYTREL® U-CUP BACK UP - METRIC

- 8700 - HYTREL® U-CUP BACK UP - INCH

- BU-T - PTFE U-CUP BACK UP - INCH

- BU-N - NYLON U-CUP BACK UP - INCH

- MBN - NYLON U-CUP BACK UP - METRIC

- MBT - SOLID TEFLON® U-CUP BACK UP - METRIC

- MB - MODULAR URETHANE U-CUP BACK UP - INCH

- BU-VEG - VEGETABLE FIBER GASKET END CAP SEAL - INCH

- WEAR RINGS / GUIDE BEARINGS

- KZT - BTFE ANGLE CUT WEARBAND w/OIL GROOVE - METRIC

- MDU - SPLIT TFE/BRONZE/STEEL ROD BUSHING - METRIC

- PSBU - SPLIT NYLON PISTON SEAL BACK UP - METRIC

- NRB - SOLID NYLON ROD BEARING - INCH

- FCB - NYLON FEMALE CENTER BEARING - INCH & METRIC

- WB - NYLON & PHENOLIC WEARBANDS - INCH

- MWB - NYLON & PHENOLIC WEARBANDS -METRIC

- WBTAPE - BTFE WEARBAND TAPE - INCH

- WBTAPE - BTFE WEARBAND TAPE - METRIC

- WBTAPE - POLY RESIN WEARBAND TAPE - INCH

- WBTAPE - POLY RESIN WEARBAND TAPE - METRIC

- WBT - T-SHAPED NYLON WEARBAND - INCH

- F1 - T-SHAPED NYLON WEARBAND - METRIC

- GEZ SPHERICAL SELF-ALIGNING BEARING - INCH & METRIC

- VEE PACKING

- VS - CHEVRON VEE PACKING SETS - INCH

- MVS - CHEVRON VEE PACKING SETS - METRIC

- VP - CHEVRON VEE COMPONENTS FAB/NBR,HYTREL®,NYLON- INCH

- VP - CHEVRON V COMPONENTS FAB/NBR,HYTREL®,NYLON -METRIC

- 6225 - AN HOMOGENOUS NITRILE CHEVRON VEE - INCH

- VP-VB - HOMOGENOUS NBR CHEVRON VEE - INCH & METRIC

- 6225 - AN TEFLON® CHEVRON VEE - INCH

- VP-VT - TEFLON® CHEVRON VEE - INCH

- THREAD, END CAP & FLANGE SEALS

- 600 - 1PC BONDED NBR/STEEL STAT-O-SEAL® - INCH

- 7500 - 1 PC SELF-CENTERING NBR/STEEL THREAD SEAL - INCH

- 400 - 1PC BONDED NBR/STEEL SEAL - INCH

- 400 - 1PC BONDED NBR/STEEL SEAL - METRIC

- OV - URETHANE SPLIT SAE FLANGE SEAL - METRIC

- SFS - UNIVERSAL URETHANE SPLIT SAE FLANGE SEAL - INCH

- CAT® REPL NITRILE SPLIT FLANGE D-RINGS (1P3XX) - INCH

- REPL HYDROLINE® & MILLER® PTFE END CAP SEALS - INCH

- HS - STATIC URETHANE HEAD SEAL - INCH

- DR - STATIC URETHANE HEAD SEAL - METRIC

- 3869 - NBR FLUID CONNECTOR FITTING SEAL - METRIC

- RET RING,CUSHION SEAL,CAP PLUG

- CP - PLASTIC CAP PLUG THREAD PROTECTORS - INCH

- SSR - STEEL VEE PACKING WAVE COMPRESSION SPRING - INCH

- MRT - NYLON or PHENOLIC CUSHION SEAL - METRIC

- V6 - PNEUMATIC URETHANE CUSHION SEAL - INCH

- 1300 - INTERNAL STEEL TRUARC® RETAINING RING - INCH

- 1400 - EXTERNAL STEEL TRUARC® RETAINING RING - INCH

- HLR - STEEL HOOK LOCK RETAINING RING - INCH

- RR - INTERNAL STEEL SPIRAL RETAINING RING - INCH

- RSI - ROUND STEEL INTERNAL RETAINING RING - INCH

- RS - EXTERNAL STEEL SPIRAL RETAINING RING - INCH

- RSE - ROUND STEEL EXTERNAL RETAINING RING - INCH

- AR - RSE U-CUP RETAINING RING - METRIC

- MNR - NYLON MAILHOT® REPLACEMENT RETAINING RING

- TELESCOPIC CYLINDER PARTS/KITS

- JOHNSON® TELESCOPIC REPLACEMENT PARTS & KITS

- COMMERCIAL/PARKER® REPLACEMENT PARTS & KITS

- CUSTOM HOIST® REPLACEMENT PARTS & KITS

- HYCO® TELESCOPIC REPLACEMENT PARTS & KITS

- HYVA® TELESCOPIC REPLACEMENT PARTS & KITS

- WARD® TELESCOPIC REPLACEMENT PARTS & KITS

- GALION® TELESCOPIC REPLACEMENT PARTS & KITS

- PERFECTION® TELESCOPIC REPLACEMENT PARTS & KITS

Z7_JA82HK02LGUEA0A51JF8DB3G77

| Please enter search criteria or click show all |

Do not alter this entry - used

for New WEB user Territory and

York, PA 17402

*Click to change your account

Switching Accounts

Are you sure you want to switch accounts?

Switching Accounts

Switching accounts in the middle of an order will clear your current cart. Are you sure you want to switch accounts?

Z7_JA82HK02LGUEA0A51JF8DB3GN4

Home

>

WEAR RINGS / GUIDE BEARINGS

>

WB - NYLON & PHENOLIC WEARBANDS - INCH

> 11.75 x 12 x 0.375 WL-0.125 Nylon Wearband Butt Cut Inch

11.75 x 12 x 0.375 WL-0.125 Nylon Wearband Butt Cut Inch

Item #:WB1200-0375-125-N1-B

Available:

81.00

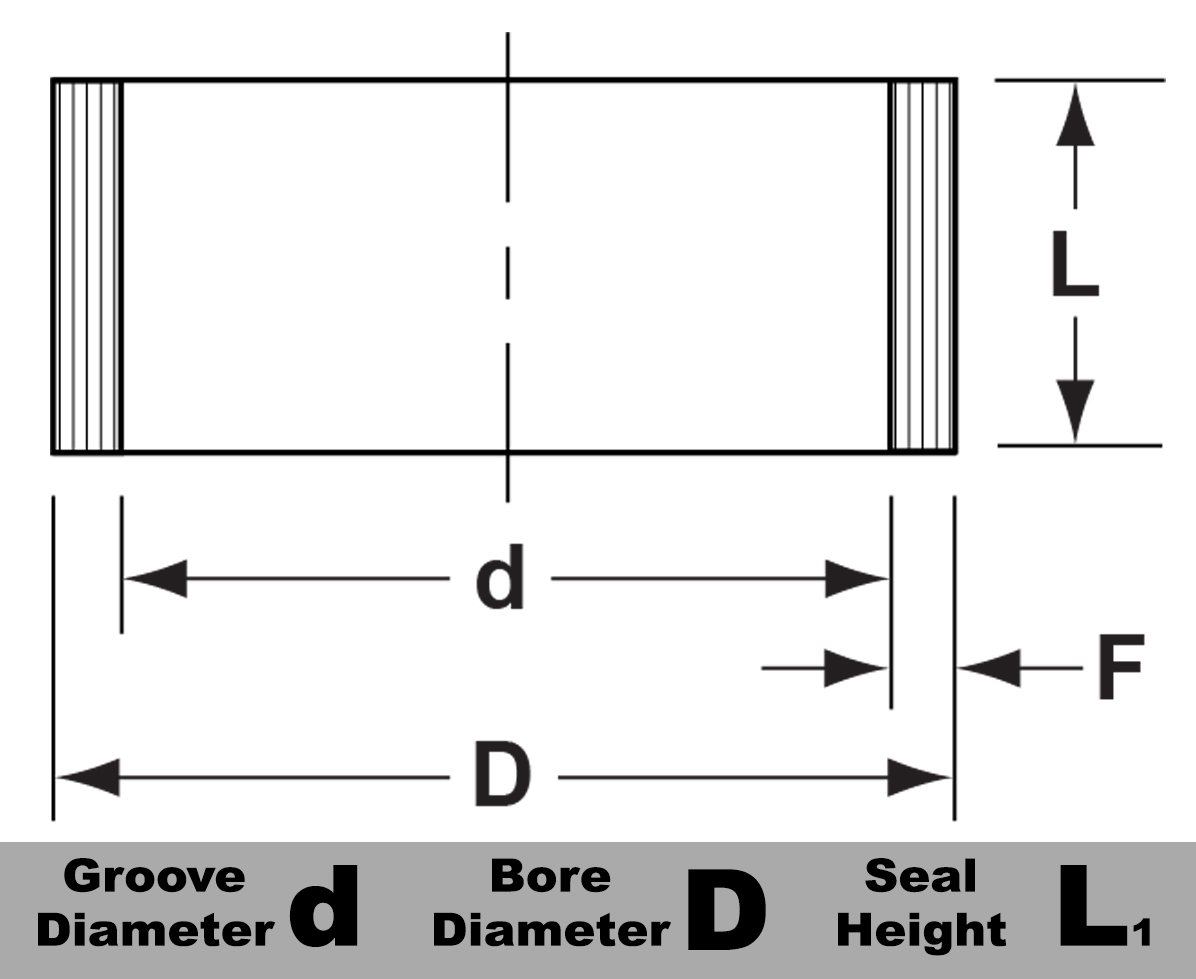

Wear rings are used to prevent metal to metal contact of moving parts in hydraulic and pneumatic cylinders. They also center the piston and rod for optimal seal life. The glass-filled nylon or phenolic material offer compressive strengths similar to most metals used for this purpose and will ingest contaminants such as metal chips, thus avoiding scoring and seal damage. Nylon wearbands are easily cut down from larger sizes to fit any size piston or rod. Consult sales for sizes not shown.

37.62

Each

Quantity:

| Quantity | Price |

| 1 | 37.62 |

ID-11.75 OD-12 HT- 0.375 WL-0.125

SPEC SHEET

11.75 x 12 x 0.375 WL-0.125 Nylon Wearband Butt Cut Inch

37.62

Each

81.00

Quantity: